About

Ansell is a diversified global leader in hand and body protection solutions and an integrated manufacturer, innovator and marketer of products on which millions of workers and healthcare professionals rely. For over 125 years, Ansell has delivered advanced protection solutions to people at work and at home, keeping them out of harm’s way. Our expertise, innovative products, and advanced technology give our customers peace of mind and confidence no other brand can deliver.

Healthcare Global Business Unit

The Healthcare GBU manufactures and markets innovative solutions for a wide range of customers, including hospitals, surgical centres, dental surgeries, veterinary clinics, first responders, manufacturers, auto repair shops, chemical plants, laboratories and life science & pharmaceutical companies.

The portfolio includes surgical gloves, single use and examination gloves, clean and sterile gloves and garments, and consumables. It also includes single use gloves used by industrial workers in manufacturing, auto repair, chemical, food processing and other industries.

HGBU

Total Revenue $1,190M

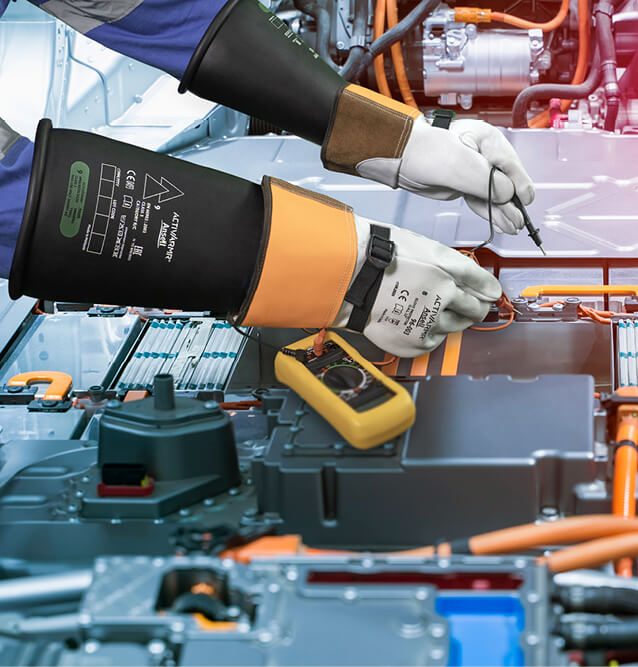

Industrial Global Business Unit

The Industrial GBU manufactures and markets high-performance hand and chemical protective clothing solutions

for a wide range of industrial applications.

Ansell protects workers in industries including automotive, chemical, metal fabrication, machinery and equipment, food, construction, mining, oil & gas, utilities, logistics and first responders.

IGBU

Total Revenue $763M

* Others predominately consists of revenue from Hércules in relation to turn-out gear for Military & First Responders, molten metal protection garments, fall protection equipment and gloves.

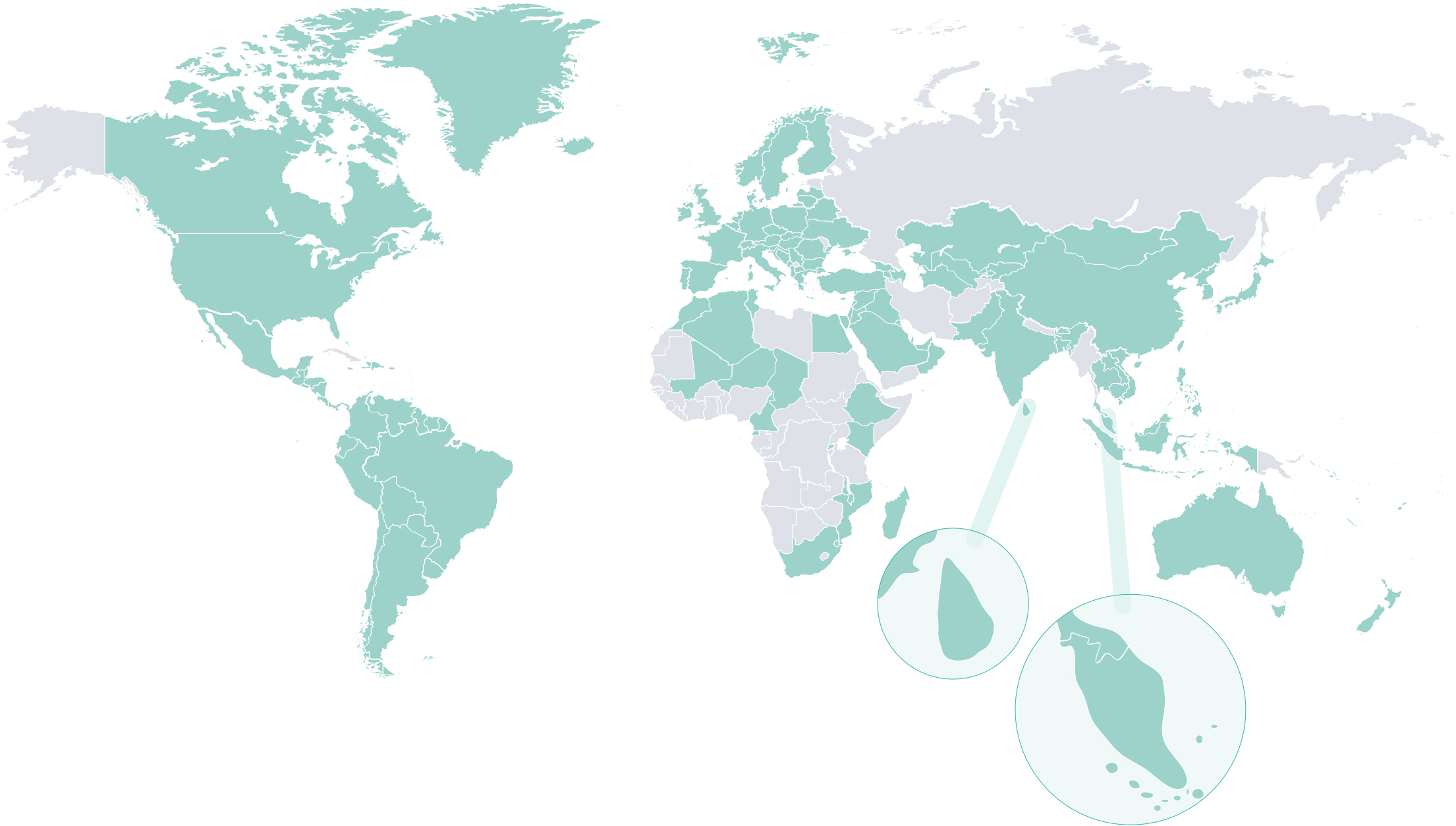

Operations

Ansell Presence

Manufacturing Facilities

Corporate Hubs

POSITION IN KEY SEGMENTS GLOBALLY

GLOVES SOLD PER YEAR

PROTECTS MORE THAN

10 MILLIONWORKERS EACH DAY

PROVIDE PROTECTION SOLUTIONS TO MORE THAN

25+ INDUSTRIESAVERAGE MEDICAL PROFESSIONAL PERSONALLY WEARS

~1200 PAIRSOF ANSELL GLOVES PER YEAR

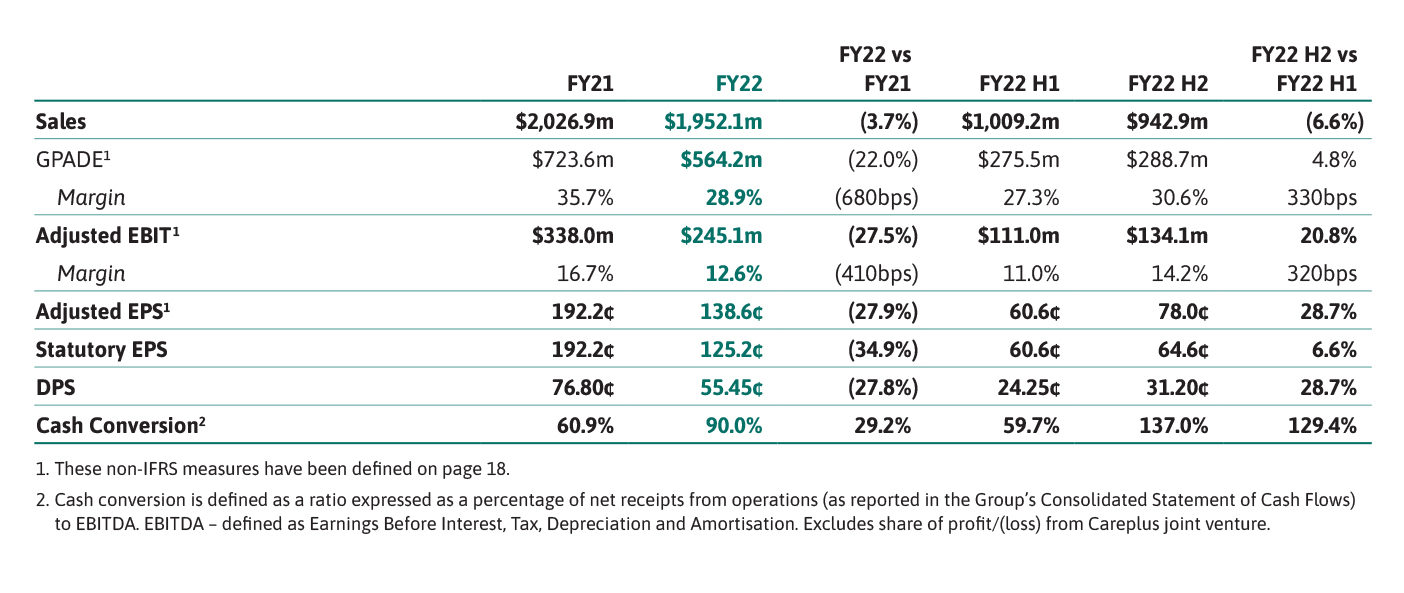

Results

-

$1,952.1m

TOTAL SALES

Adjusted EBIT margin(1) 12.6%

-

$1,189.6m

HGBU SALES

EBIT margin 12.7%

-

$762.5m

IGBU SALES

EBIT margin 14.0%

-

90%

CASH CONVERSION

(1) Adjusted EBIT margin based on EBIT adjusted to exclude expenses associated with Russia Business Disruption and Exit.

Performance in FY22 – Overview

Chairman’s Review

With the crisis phase of the pandemic behind us we are confident that its long-term impact will be to enhance safety awareness and highlight the vital role of high-quality PPE.

READ MORE

Chief Executive Officer’s Review

Though we have a very impressive record compared to companies in our sector, we are committed to improving our safety performance further in FY23.

READ MOREYear in review

- India Greenfield Manufacturing Site

- EcoVadis Silver medal

- New Targets

- Inteliforz™ Launched

- Integrated Business Planning (IBP)

Commencement of an $80m investment over the next three years for a new manufacturing site in Tamil Nadu, southern India. The facility will be designed and built in line with Indian Green Building Council criteria and have the capability to produce a wide range of products, with an initial focus on surgical and life science gloves for the Indian domestic market and for export.

Ansell was awarded a silver medal by EcoVadis based on reporting data for FY21, placing it in top 25% of all companies assessed and the top 6% of manufacturers within our applicable industry1.

1. EcoVadis classified Ansell in “other manufacturing n.e.c. (nowhere else classified)” industry.

Ansell has committed to science-based reduction targets for Scope 1 and Scope 2 emissions that would see the Company achieve Net Zero by 2040 for its own operations. This is supported by a mid-term target of a 42% reduction by 2030, from a FY20 baseline. Ansell will focus on long-term decarbonisation efforts within its own operations, prior to exploring investment in credible and high-quality offsets to address any limited residual emissions (less than 10%).

Inteliforz™, our newest brand, is focused on connected workplace safety solutions that empower front-line associates and safety leaders to “See Beyond the Obvious™” to prevent injuries before they happen. Commercially, Inteliforz™ was successfully deployed at a large multinational corporation with trials underway at a number of other companies. Significant brand and thought leadership progress has been achieved, including securing a sponsorship role and advisory council seat with the National Safety Council MSD Pledge, aimed at reducing occupational musculoskeletal disorders (MSD) injuries by 25% by 2025.

Redesigned sales and operations planning process with a strong focus on improving customer service levels. This innovative approach is supported by an overhaul of data architecture and planning systems and with the objective to move Ansell to a leading position in supply chain capability.

Sustainability

We are passionate about protecting people, setting ourselves ambitious goals to transform our company and to protect sustainably both employees and the environment we live in. Ansell has put sustainability at the heart of its business with our purpose: thinking of people and planet first.

People

The industry Ansell operates in, and the location of many of our operations and suppliers, expose us to higher risks of labour exploitation. Ansell is committed to respecting human rights and will not tolerate conditions of modern slavery. These are complex, systemic issues, and as a market leader Ansell is acting to promote high labour standards across our operations, supply chain and the wider industry.

READ MORE

Planet

In July 2022, we announced an ambitious decarbonisation strategy which will see Ansell achieve Net Zero by 2040 for our own operations. This long-term reduction target is supported by a science-based mid-term target of 42% reduction in Scope 1 and 2 emissions by 2030, from a FY20 baseline, in line with the ambitions of the Paris Agreement to limit global warming to 1.5 degrees Celsius. Ansell will focus on long-term decarbonisation efforts within its own operations, prior to exploring investing in credible and high-quality off-sets to address any limited residual emissions (less than 10%).

READ MORE

Product

During FY22 we accelerated the integration of Design for Sustainability principles into our innovation and product processes, incorporating data derived from life cycle assessments and customers’ needs. We also finalized our packaging pledge and accomplished significant projects to eliminate, reduce and replace packaging material during the year.

READ MORE